Schedule 40 Stainless Steel Pipe chart

- home

- Pipes

Stainless Steel SCH40s Pipe, Schedule 40 SS 304 pipe, Check Schedule 40 Stainless Steel Pipe Strength

Steel pipes are fabricated in different schedules within set industrial standards and have different thicknesses of the wall. Where the higher the schedule number, the higher will be the thickness of the wall. The schedule pipes are designed for specific applications and are personalized accordingly. Just like other grades, the schedule 40 pipes are also fabricated for medium to low pressure applications due to the thickness of the wall, and these pipes are also known as moderate schedule pipes. Even with moderate wall thickness, these pipes show great character in various environmental conditions, provide higher resistance to various corrosions, prevent oxidation, and protect the metal from rapture breaking.

Schedule 40 Stainless Steel Pipe

ss 304 schedules 40 pipes

Schedule 40S Seamless Pipe

The schedule 40 pipes are made from mild steel or low carbon and have a zinc coating, done in two different ways: in line galvanization and hot dip galvanization. Where the hot dip galvanizing method is most commonly used to prevent the metal from rusting. Also in some cases stainless steel is employed to get higher resistance from corrosion.

Though it has high anti-corrosion properties, this grade of pipes have comparatively thin wall thickness. Hence, choosing the scheduled pipes as per customers' requirements for their specified pressure applications is recommended. A change in pressure can affect these pipes extensively. Here the pipes with a diameter of 1/8” has a wall thickness of 1.727mm, and where the diameter is 24” the wall thickness goes up to 9.525mm. Each variant has different pressure bearing capacity ranging from low to moderate.

Schedule 40 Stainless Steel Pipes Dimension

| Nominal size [inches] | Outside diameter [inches] | Outside diameter [mm] | Wall thickness [inches] | Wall thickness [mm] | Weight [lb/ft] | Weight [kg/m] |

|---|---|---|---|---|---|---|

| 1/2 Inches | 0.840 Inches | 21.3 MM | 0.065 Inches | 1.65 MM | 0.54 lb/ft | 0.80 kg/m |

| 3/4 Inches | 1.050 Inches | 26.7 MM | 0.065 Inches | 1.65 MM | 0.69 lb/ft | 1.03 kg/m |

| 1 Inches | 1.315 Inches | 33.4 MM | 0.065 Inches | 1.65 MM | 0.87 lb/ft | 1.30 kg/m |

| 1 1/4 Inches | 1.660 Inches | 42.2 MM | 0.065 Inches | 1.65 MM | 1.12 lb/ft | 1.66 kg/m |

| 1 1/2 Inches | 1.900 Inches | 48.3 MM | 0.065 Inches | 1.65 MM | 1.28 lb/ft | 1.91 kg/m |

| 2 Inches | 2.375 Inches | 60.3 MM | 0.065 Inches | 1.65 MM | 1.61 lb/ft | 2.40 kg/m |

| 2 1/2 Inches | 2.875 Inches | 73.0 MM | 0.083 Inches | 2.11 MM | 2.49 lb/ft | 3.71 kg/m |

| 3 Inches | 3.500 Inches | 88.9 MM | 0.083 Inches | 2.11 MM | 3.05 lb/ft | 4.54 kg/m |

| 3 1/2 Inches | 4.000 Inches | 101.6 MM | 0.083 Inches | 2.11 MM | 3.50 lb/ft | 5.21 kg/m |

| 4 Inches | 4.500 Inches | 114.3 MM | 0.083 Inches | 2.11 MM | 3.95 lb/ft | 5.88 kg/m |

| 5 Inches | 5.563 Inches | 141.3 MM | 0.109 Inches | 2.77 MM | 6.40 lb/ft | 9.52 kg/m |

| 6 Inches | 6.625 Inches | 168.3 MM | 0.109 Inches | 2.77 MM | 7.65 lb/ft | 11.38 kg/m |

| 8 Inches | 8.625 Inches | 219.1 MM | 0.109 Inches | 2.77 MM | 9.99 lb/ft | 14.87 kg/m |

| 10 Inches | 10.750 Inches | 273.1 MM | 0.134 Inches | 3.4 MM | 15.29 lb/ft | 22.76 kg/m |

| 12 Inches | 12.750 Inches | 323.9 MM | 0.156 Inches | 3.96 MM | 21.13 lb/ft | 31.44 kg/m |

| 14 Inches | 14.000 Inches | 355.6 MM | 0.156 Inches | 3.96 MM | 23.22 lb/ft | 34.56 kg/m |

| 16 Inches | 16.000 Inches | 406.4 MM | 0.165 Inches | 4.19 MM | 28.11 lb/ft | 41.83 kg/m |

| 18 Inches | 18.000 Inches | 457.0 MM | 0.165 Inches | 4.19 MM | 31.64 lb/ft | 47.09 kg/m |

| 20 Inches | 20.000 Inches | 508.0 MM | 0.188 Inches | 4.78 MM | 40.12 lb/ft | 59.70 kg/m |

| 22 Inches | 22.000 Inches | 559.0 MM | 0.188 Inches | 4.78 MM | 44.18 lb/ft | 65.75 kg/m |

| 24 Inches | 24.000 Inches | 610.0 MM | 0.218 Inches | 5.54 MM | 55.85 lb/ft | 83.11 kg/m |

| 30 Inches | 30.000 Inches | 762.0 MM | 0.250 Inches | 6.35 MM | 80.02 lb/ft | 119.09 kg/m |

At N-pipes, we have experts with years of experience to guide our customers to choose a suitable product for their applications and requirements. We have satisfied clients across India and various countries using our Schedule 40 pipes for various applications like water lines, pulp, paper industries, construction, and more. We provide all necessary certificates only after testing all our products to ensure profound quality at inexpensive rates.

We provide the best competitive prices to our clients backed by quality service.

SCH 40 SS Pipe Wall Thickness

| Nominal size [inches] | Outside diameter [inches] | Outside diameter [mm] | Wall thickness [inches] | Wall thickness [mm] | Weight [lb/ft] | Weight [kg/m] |

|---|---|---|---|---|---|---|

| 1/2 | 0.840 | 21.3 | 0.083 | 2.11 | 0.68 | 1.00 |

| 3/4 | 1.050 | 26.7 | 0.083 | 2.11 | 0.87 | 1.29 |

| 1 | 1.315 | 33.4 | 0.109 | 2.77 | 1.41 | 2.11 |

| 1 1/4 | 1.660 | 42.2 | 0.109 | 2.77 | 1.82 | 2.71 |

| 1 1/2 | 1.900 | 48.3 | 0.109 | 2.77 | 2.1 | 3.13 |

| 2 | 2.375 | 60.3 | 0.109 | 2.77 | 2.66 | 3.96 |

| 2 1/2 | 2.875 | 73.0 | 0.120 | 3.05 | 3.56 | 5.29 |

| 3 | 3.500 | 88.9 | 0.120 | 3.05 | 4.37 | 6.50 |

| 3 1/2 | 4.000 | 101.6 | 0.120 | 3.05 | 5.01 | 7.46 |

| 4 | 4.500 | 114.3 | 0.120 | 3.05 | 5.66 | 8.42 |

| 5 | 5.563 | 141.3 | 0.134 | 3.40 | 7.82 | 11.64 |

| 6 | 6.625 | 168.3 | 0.134 | 3.40 | 9.35 | 13.91 |

| 8 | 8.625 | 219.1 | 0.148 | 3.76 | 13.50 | 20.10 |

| 10 | 10.750 | 273.1 | 0.165 | 4.19 | 18.79 | 27.96 |

| 12 | 12.750 | 323.9 | 0.180 | 4.57 | 24.34 | 36.22 |

| 14 | 14.000 | 355.6 | 0.188 | 4.78 | 27.97 | 41.62 |

| 16 | 16.000 | 406.4 | 0.188 | 4.78 | 32.02 | 47.65 |

| 18 | 18.000 | 457.0 | 0.188 | 4.78 | 36.05 | 53.65 |

| 20 | 20.000 | 508.0 | 0.218 | 5.54 | 46.42 | 69.09 |

| 22 | 22.000 | 559.0 | 0.218 | 5.54 | 51.14 | 76.10 |

| 24 | 24.000 | 610.0 | 0.250 | 6.35 | 63.93 | 95.13 |

| 30 | 30.000 | 762.0 | 0.312 | 7.92 | 99.60 | 148.22 |

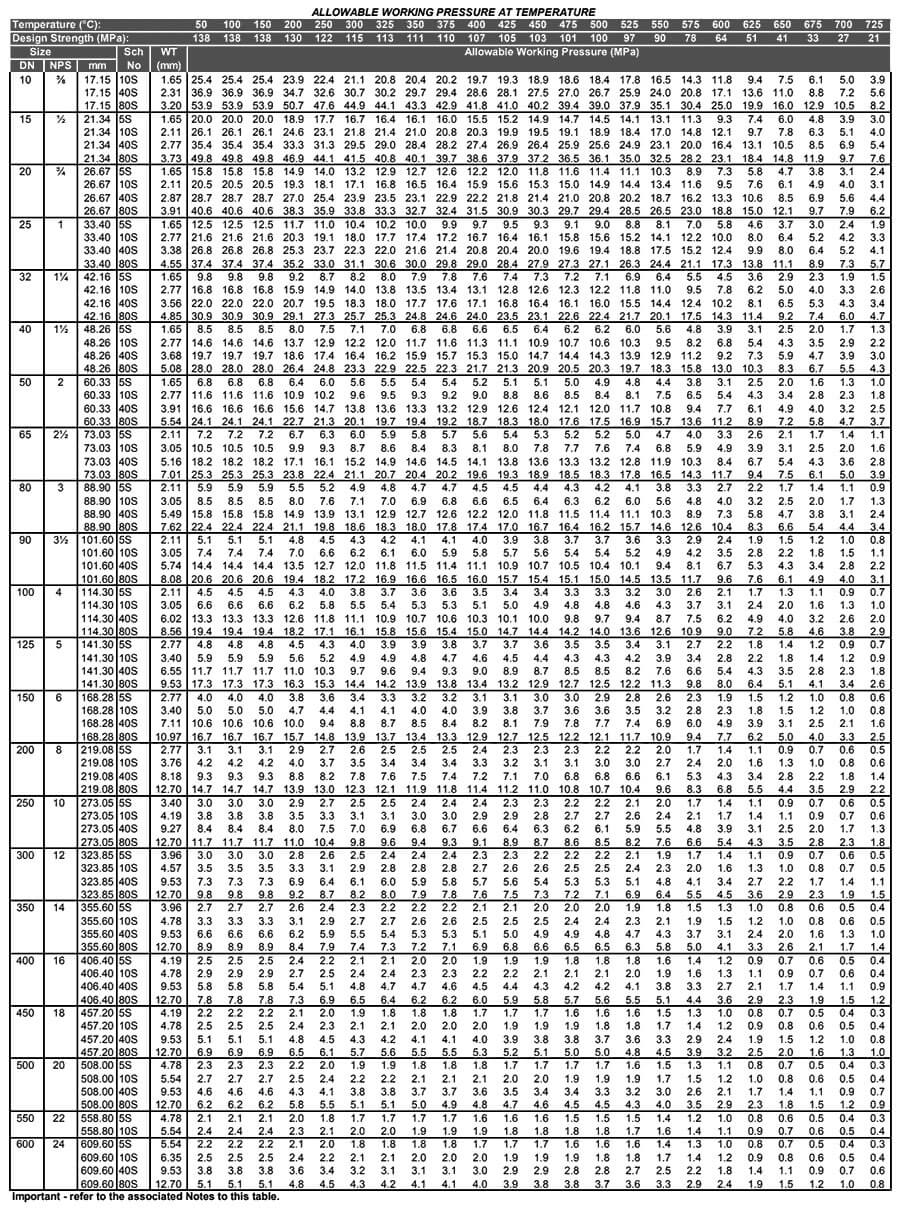

Pressure Rating Of Seamless schedule 40S pipe

Ordering Information

The purchase order shall include the quantity, PSL level, type or Grade, reference to API5L, outside diameter, wall thickness, length and any applicable annexes or additional requirements related to chemical composition, mechanical properties, heat treatment, additional testing, manufacturing process, surface coatings or end finish.